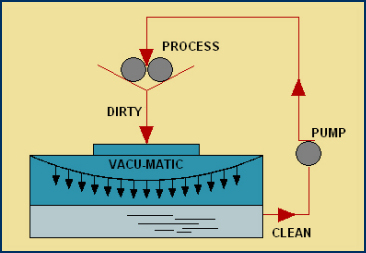

The feeder pump supplies

the Vacu-Matic with contaminated process liquid from the

dirty tank. This liquid is pumped to the distributor, where it is evenly portioned

across

the pool on the filter bed. The bed consists of a flat wire belt supporting

the filter media

itself.

A Gardner Denver exhauster produces vacuum in the chamber beneath the filter

bed,

drawing the liquid through the media and the built-up deposit of solids (filter

cake).

When the pressure drop across the filter cake/media reaches a given limit,

an electrical

switch is closed. This indexes the media and dried filter cake into the disposal

container.

At the same time, clean filter media is drawn onto the filter bed. Both the

vacuum in the

vacuum chamber and the liquid level drop due to the inrush of liquid through

the fresh

media. This sudden flow builds the filter cake back to a functional level.

The clean liquid passing through the filter cake and media drains into the

clean liquid

compartment of the holding tank. A "water leg" is maintained in

the clean overflow

pipe to sustain a vacuum in the filter.

Where excessive floating solids or tramp oil exist in the incoming process

liquid, discharge air from the vacuumproducer can be used to operate the standard

air skimmer.

This moves any loose floating materials toward the dirty

end of the filter for removal as media is indexed.

Should the filter bed become flooded due to mechanical malfunction or unexpected

impurities in the process, the

liquid level is reduced via the overflow slot connected to the side gutter.

This is connected to an overflow drain

pipe dumping into the dirty compartment of the holding tank.

The Hoffman Compact Vacu-Matic

operates using the same principles as the

larger Hi-Flo unit.

The difference is that the Compact has its own clean liquid reservoir, with

dirty liquid often being fed directly to the filter, while the Hi-Flo requires

the

storage of all liquids in separate tanks or sumps.

This makes the Compact ideally suited for small to medium sized applications,

particularly in plants where space is restricted. Models are available for

flow

rates from 20 GPM (75.7 LPM) to 240 GPM (908.4 LPM). Units are supplied

with both exhauster and pump motors pre-wired to a junction box for easy

installation.

The Compact offers all the advantages of flat

bed vacuum filtration:

![]() Removal of tramp oil and floating solids

Removal of tramp oil and floating solids

![]() Coolant aeration to

curtail bacterial growth

Coolant aeration to

curtail bacterial growth

![]() Continuous coolant flow

while indexing

Continuous coolant flow

while indexing

![]() Easy to install, simple

to operate controls

Easy to install, simple

to operate controls